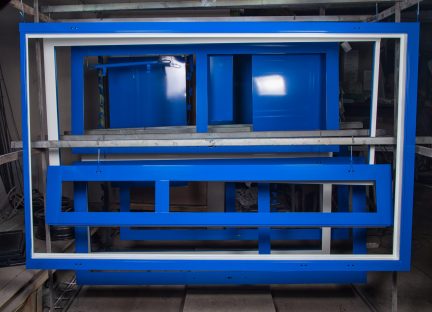

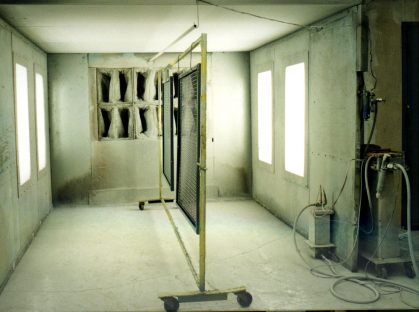

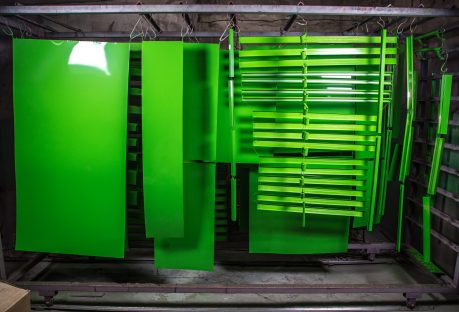

At Excell Coatings, our powder coating services involve applying a powder made of fine particles and resin to a surface using an electrostatic charge. The charged powder particles stick to the surface and are then heated in one of our curing ovens. The result is a uniform, durable and high-quality finish.

At our Florida facility, we use the most updated materials for coatings, including epoxy, polyester, T.G.I.C., polyurethane, hybrid, nylon, vinyl, as well as other highly durable coatings that meet AAMA 2604 and AAMA 2605.

Powder coating benefits

Why choose powder coating? Here are just a few reasons:

- Durability – Powder coating is extremely long-lasting, resistant to chipping, scratching, fading and corrosion.

- Choice – With powder coating, your choice of colors is virtually endless – and we can offer you a wide selection of finishes including gloss, flat, matte & textures

- Price – Because powder coating produces less waste and fewer VOCs (volatile organic compounds), it’s faster, easier and less expensive for companies to comply with EPA rules and regulations

- Environmentally friendly – Unlike liquid finishes (which contain solvents and other pollutants), powder coating does not release high quantities of harmful VOCs into the atmosphere and is therefore safer for the environment.

Excell’s enhanced coating services:

- M.I & R.F.I. Shielding Liquid Process: For electrical conductivity or shielding on non-metallic parts

- Pretreat & outsource plating: Enhances adhesion and provides additional corrosion resistance

- Precision masking, masked spraying: Provided for all coating systems

- Filling: For filling depressions or voids in parts where necessary before coating.

Common applications include:

- Industrial parts of all sizes

- Military coatings (mil-spec coating) – interior, exterior, marine, etc.

- Steel, copper, aluminum & bronze plates, parts & equipment

- Metal & plastic piping

- Wrought iron gates, furniture & parts

- Signage & shelving units

- Car, ATV, motorcycle & bicycle parts, wheels and frames